Top 5 Highway Barriers for Work Zone Safety

Innovative Highway Barriers such as Mobile Barriers, Movable Barriers, & Temporary Barriers enable engineers and contractors to accelerate highway projects, increase roadway capacity to match daily traffic patterns, physically separate moving traffic and workers, minimize workzone footprints, and increase work zone safety.

The serious hazards faced by highway workers, who are among the most "Vulnerable Road Users", makes it vitally important that engineers and contractors use Positive Protection work zone barriers to ensure worker safety. In a 2022 survey, 64% of highway contractors reported crashes into their work zones. [24] In an earlier survey, 89% of highway contractors think Positive Protection barriers would help improve safety and prevent these horrific crashes. [4]

ANSI Standard A10.47-2021 (§4.4) and Federal Regulations direct that positive protection “shall be used” in, at minimum, 5 circumstances. In 2021, the Infrastructure Investment and Jobs Act (IIJA) amended the Highway Safety Improvement Program (HSIP) to add protection for "Vulnerable Road Users", which includes road construction & highway workers on foot in work zones.

In 2021, California launched its award-winning Caltrans Positive Protection Program which directs Caltrans design engineers and contractors to use Positive Protection to ensure worker safety. California research found a cost benefit for highly mobile barrier of $1.9 million per year, per barrier in 2008 ($2.87 million in 2025 dollars). 14

Today, we have the technology, 'know how', and responsibility to protect workers from errant vehicles by using Positive Protection work zone barriers.

“A physical barrier provides one of the best possible protection solutions for workers exposed to the flow of traffic. [Implementing Positive Protection] is a common-sense and cost-effective way for safety reform that will prevent death and injuries of workers on roads and highways.”

Types of Positive Protection Barrier

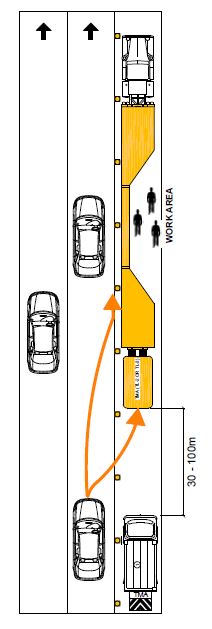

Mobile Barrier

Mobile Barriers MBT-1® is a innovative traffic barrier system for work zones & incident response. The mobility of the MBT-1® allows rapid work zone setup/removal and enables engineers and managers to reduce project duration & cost, schedule around peak traffic hours, and minimize roadway congestion. The MBT-1® provides positive protection for a wide range of projects including short-duration and short-term work zones, road & bridge construction & maintenance, moving operations, incident management, and more. The MBT-1® has been called the "perfect tool" for various types of road, bridge, and tunnel projects.

The MBT-1® provides 42-102 feet of positive protection with minimal deflection and is tested and accepted under NCHRP 350 & MASH for TL-2 and TL-3 usage. Beyond its protective capabilities, the workhorse MBT-1® offers 85,000 lbs (38500 kg) GVWR carry capacity, optional crane & heavy lifting capabilities, generator power, high-lumen work lights for night operations, signage (e.g. matrix or arrow board), truck mounted attenuator (TMA), lockable storage, and more for enhanced safety and productivity on-site.

Mobile Barrier

Mobile Barriers MBT-1® is a innovative traffic barrier system for work zones & incident response. The mobility of the MBT-1® allows rapid work zone setup/removal and enables engineers and managers to reduce project duration & cost, schedule around peak traffic hours, and minimize roadway congestion. The MBT-1® provides positive protection for a wide range of projects including short-duration and short-term work zones, road & bridge construction & maintenance, moving operations, incident management, and more. The MBT-1® has been called the "perfect tool" for various types of road, bridge, and tunnel projects.

The MBT-1® provides 42-102 feet of positive protection with minimal deflection and is tested and accepted under NCHRP 350 & MASH for TL-2 and TL-3 usage. Beyond its protective capabilities, the workhorse MBT-1® offers 85,000 lbs (38500 kg) GVWR carry capacity, optional crane & heavy lifting capabilities, generator power, high-lumen work lights for night operations, signage (e.g. matrix or arrow board), truck mounted attenuator (TMA), lockable storage, and more for enhanced safety and productivity on-site.

Moveable Barrier - Concrete

Lindsay Transportation Solutions QMB Zipper: The Road Zipper System is designed to increase capacity and reduce congestion by making more efficient use of new or existing roadways & highways. This technology is used for managed lanes and construction applications to create safe, dynamic highways that offer real-time roadway reconfiguration while maintaining positive barrier protection between lanes. The Road Zipper System can be used to move barrier from one side of a lane to the other to create work space and reopen lanes again to restore capacity.

Moveable Barrier - Concrete

Lindsay Transportation Solutions QMB Zipper: The Road Zipper System is designed to increase capacity and reduce congestion by making more efficient use of new or existing roadways & highways. This technology is used for managed lanes and construction applications to create safe, dynamic highways that offer real-time roadway reconfiguration while maintaining positive barrier protection between lanes. The Road Zipper System can be used to move barrier from one side of a lane to the other to create work space and reopen lanes again to restore capacity.

Moveable Barrier - Steel

Valtir's Vulcan® moveable steel barrier is comprised of lightweight, galvanized steel segments that offers real-time roadway reconfiguration. It is tested to NCHRP Report 350 Test Level 3 and Test Level 4, and EN1317 H2 and N2 specifications. The Vulcan® Moveable Barrier is designed for easier movement with the Vulcan® Transfer Attachment (VTA) when connected to a skid steer or front end loader. The VTA is also designed to help the operator work from either side of the barrier.

Moveable Barrier - Steel

Valtir's Vulcan® moveable steel barrier is comprised of lightweight, galvanized steel segments that offers real-time roadway reconfiguration. It is tested to NCHRP Report 350 Test Level 3 and Test Level 4, and EN1317 H2 and N2 specifications. The Vulcan® Moveable Barrier is designed for easier movement with the Vulcan® Transfer Attachment (VTA) when connected to a skid steer or front end loader. The VTA is also designed to help the operator work from either side of the barrier.

Temporary Steel Barrier

Hill & Smith Zoneguard® temporary steel barrier, offers the road construction industry a revolutionary temporary barrier solution that provides superior protection. A cost-effective alternative to traditional concrete barrier, Zoneguard’s lightweight configuration allows 750 feet to be hauled on one truck and up to 1500 feet to be installed in one hour. Zoneguard’s low weight does not affect its performance, as it meets both NCHRP 350 (TL-3 & TL-4) and MASH (TL-3) crash test standards.

Temporary Steel Barrier

Hill & Smith Zoneguard® temporary steel barrier, offers the road construction industry a revolutionary temporary barrier solution that provides superior protection. A cost-effective alternative to traditional concrete barrier, Zoneguard’s lightweight configuration allows 750 feet to be hauled on one truck and up to 1500 feet to be installed in one hour. Zoneguard’s low weight does not affect its performance, as it meets both NCHRP 350 (TL-3 & TL-4) and MASH (TL-3) crash test standards.

Traditional Temporary Concrete Barrier (TCB)

Traditional temporary concrete barrier is generally considered a device for use on Long-Term Projects. With a weight of 4,000 lbs or more, temporary concrete barrier requires heavy equipment to install, rearrange, and remove at the end of a project. As a result, temporary concrete barrier is often left-in-place for the duration of a project, limiting roadway capacity & flexibility to respond to rush hour traffic congestion. Commonly cited challenges of using concrete Jersey Barrier or K-Rail include installation/removal time & cost, safety risks of installation/removal in live traffic, and impracticality for Short-Term and Short-Duration work zones and/or where it is desirable to reopen lanes and relieve congestion for rush hour highway traffic.

Traditional Concrete Barrier (TCB)

Traditional concrete K-rail or Jersey Barrier is generally considered a device for use on Long-Term Projects. With a weight of 4,000 lbs or more, concrete Jersey Barrier requires heavy equipment to install, rearrange, and remove at the end of a project. As a result, traditional concrete barrier is often left-in-place for the duration of a project, limiting roadway capacity & flexibility to respond to rush hour traffic congestion. Commonly cited challenges of using concrete Jersey Barrier or K-Rail include installation/removal time & cost, safety risks of installation/removal in live traffic, and impracticality for Short-Term and Short-Duration work zones and/or where it is desirable to reopen lanes and relieve congestion for rush hour highway traffic.

Anchoring temporary concrete barrier (TCB) reduces deflection. However, anchoring TCB increases installation/removal time & cost.

Unanchored/free-standing temporary concrete barrier (TCB) has greater lateral deflection. Unanchored TCB requires additional buffer/clear area which may reduce roadway capacity.

EV pickup, 62mph @ 25° angle crash test video: In a 2024 electric vehicle (EV) crash test, temporary concrete barriers were pushed back 10 ft (50% more than normal). “Anybody on the back side of that barrier could have been pushed off the side of a bridge” noted the lead investigator. With the trend towards heavier vehicles (trucks/SUVs account for 81.5% of new vehicles sales as of January 2025), it’s more important than ever to take into account the make-up of the U.S. fleet and to upgrade to crashworthy speed-appropriate barriers between live traffic and work zones.

|

"We have the technology and 'know how' to build our roadway system to anticipate user error. It can be designed, constructed, equipped, and operated to forgive the errant user and protect the innocent victim." |

"We have the technology and 'know how' to build our roadway system to anticipate user error. It can be designed, constructed, equipped, and operated to forgive the errant user and protect the innocent victim."

Footnotes

Project 5:"In this particular project, a great number of unexpected issues appeared: ... an accident forced [the project management team] to include stricter safety systems [which required rework]." Project 8: "Incomplete project documentation such as extra safety conditions or enlargement of car protections in case of impact provoked rework activities."

"Abdul-Rahman (1995) determined non-conformance costs in a highway projectto be 5% ofthe contract value (excluding material wastage and head office overhead). Abdul-Rahman specifically points outthat non-conformance costs may be significantly higher where poor quality management practices were implemented."