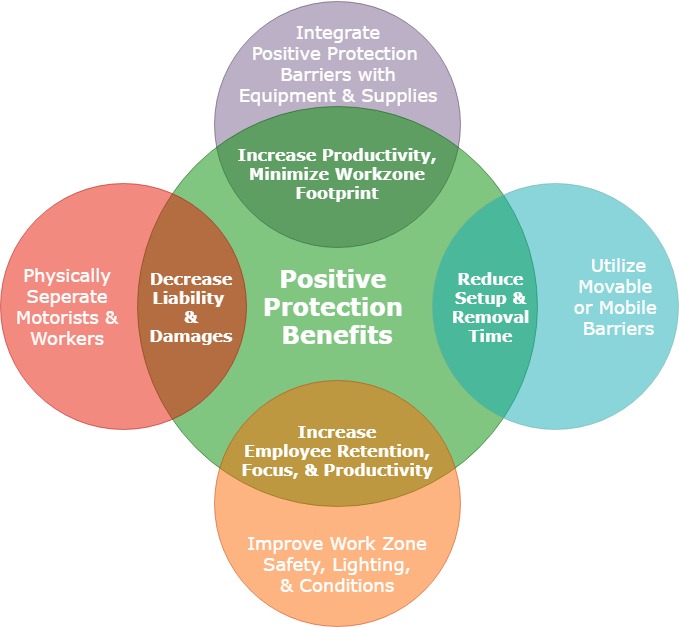

What are the Benefits of Using Positive Protection Barriers for Work Zone Safety?

Improved road-user and worker safety is a proven benefit from using positive protection. New types of positive protection barriers can be used to meet regulations and standards, physically separate moving traffic and workers, and provide practical cost-effective work zone safety.

Cost Benefits

California research found a cost benefit for highly mobile barrier of $1.9 million in 2008 dollars ($2.87 million in 2025 dollars) per year, per barrier. 14 In 2024, USDOT set the value of a single life (VSL) at $13.7 million dollars. [13] [37] When comparing the cost of the life of a worker to positive protection's cost and 20 year expected term of use, the annual cost of using positive protection is minimal. Over 20 years of use, the barrier will most likely save one or more lives and help avoid even more injuries, accidents, and delays.

Commonly Cited Benefits

Benefits vary by product and application. Commonly cited benefits of using positive protection include:

- Safeguarding Workers Against Intrusions

- Increasing Worker Focus on Tasks

- Reducing Setup

- Increasing Productivity with Onboard Tools and Supplies

- Increasing Efficiency/Saving Time

- Increasing Employee Retention

- Decreasing Liability and Damages

- Reducing Risk and Exposure to Dangers of Live Work Zone

Benefits for Workers and the Public

Positive protection benefits workers & the traveling public by both improving safety and mobility in and around work zones.

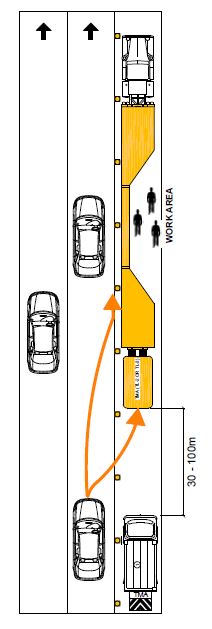

Truck or Trailer Mounted Attenuators (TMA) and warning devices (rumble strips, alarms, etc.) help but also permit motorists to veer around these devices and swerve back into the work zone. At 50 mph, errant drivers may have less than 1 second to realize and correct their mistakes. In an analysis of impacts in one work zone location, 30-40% of the incidents involved direct rear impacts, and 60-70% of the incidents involved lateral incursions (with relatively tight TMA spacing).

15

Drivers make mistakes but mistakes need not be catastrophic – for drivers, workers, or others.

Positive Protection physically separates workers and motorists. Barriers are designed to prevent logitudinal and lateral crashes into work zone zones. Barriers help drivers better focus on the road ahead and help reduce the severity of mistakes and accidents. In many cases, errant drivers can regain control and continue on their way.

Extended lane closures with low work activity contribute to driver frustration. Traditional practices of taking buffer lanes are not needed and are becoming impractical with increasing traffic volumes. Positive protection helps reduce the number and duration of lane closures. Work and associated protection can be focused in one or more specific areas.

The highly mobile and movable types of barriers are designed to help reopen the roadway quickly to restore capacity. Roadways can be reopened daily to ease rush hour traffic otherwise congested behind work zones. Reducing congestion benefits both motorists & workers. Speed variance (i.e. congestion/slowdowns) is a significant contributor to accidents in and around work zones. Those accidents may cause additional crashes and/or spill over into work zones. Addressing congestion with positive protection can benefit workers, the public, and commerce by reducing accidents, injuries, fatalities, risk, delay, and interruption. These combined considerations accounted for much of the $1.9 million savings per highly mobile barrier per year found by California DOT research.

14

3 year/$150-200 million project.

3x mobile barriers:- 10-20% time savings per night.

- Lanes reopen daily.

- Lane shifts improve traffic flow.

- Reduced project duration & cost.

- Optimal traffic flows.

An ongoing project in California illustrates even greater potential savings on projects and benefits for the public. Highly mobile barriers are saving an estimated 1-2 hours per night on setup/removal (a 10-20% savings in time and potential project duration). In one closed lane, they are using three barriers to work at different spots along that lane. On a three-year, $150-200 million project, that amounts to substantial reduction in project duration and cost. For the public, benefits are increased even further by shifting lanes around the work zone using movable concrete barrier. Used together, the highly mobile and movable barriers better maintain traffic flows and reduce overall project duration.